We realize not every detail is obvious at first glance, so this series is intended to provide an inside look into the thought and design process behind our creations – and yes, perhaps a sneak peak or two at the future.

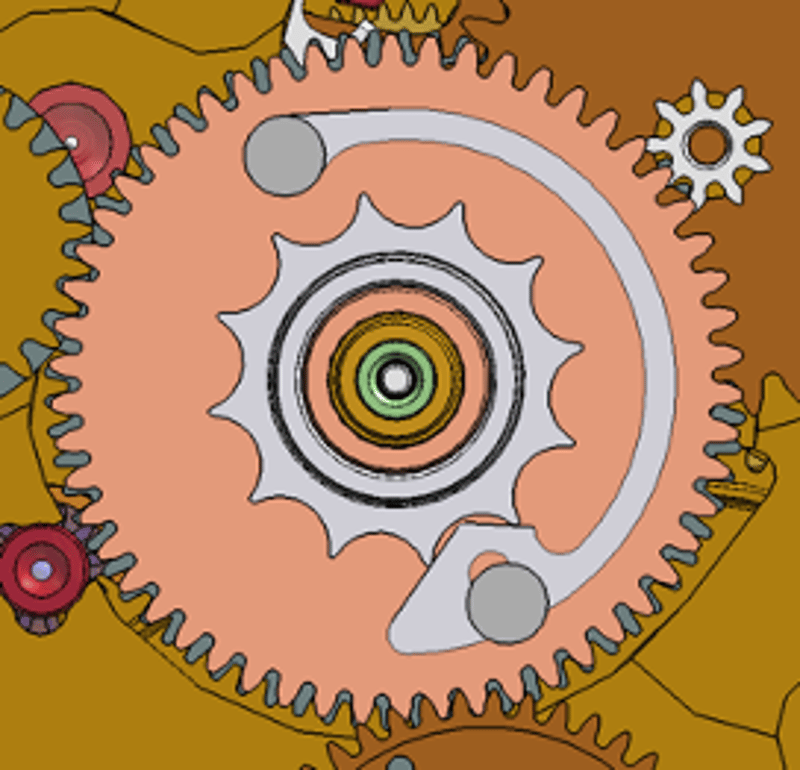

Pictured to the left is the core of the independent hours mechanism used in the 17.09. Our ‘petit complication’ based off this movement was to run the hour hand off what was the previous 24h pinion, but re-geared to 12h – in effect creating an hour hand that could be easily adjusted when travelling or for daylight savings without losing your main time. In concept, this change is simple: decrease the reduction ratio between pinions, and change the 24-tooth setting star for a 12-tooth one.

We used the 24h GMT mechanism of the Sellita SW330-1 as a base; however between development and production, the SW330-1 was discontinued and the SW330-2 took its place. Everything supposedly the same, but improved to address 24h hand slack/ play present in the -1. Even better for us, since we would be using this as the main hour hand.

As it turns out…there were some undocumented changes and these affected both the tension of the GMT and setting mechanisms. This was the underlying cause of the alignment issues affecting some of the early 17.09s: firstly, if not backwound half a turn to disengage the switching rocker (bottom white round gear in illustrations below), the setting gear would cause drag on the 24/12h hand causing it to lag. In these cases, resetting the time but turning the crown one revolution in the second position to disengage the independent hour mechanism before pushing it back in would solve the problem.

Secondly, in other cases (and frustratingly, at times exacerbating the first issue), the profile of the spring and tooth was not ‘sharp’ enough to hold in place against the friction from the new, tighter pinions or against the drag of the setting mechanism. This is a delicate balancing act: too tight and the watch is difficult to set, or stops entirely. Too loose and the hour hand becomes slackly coupled to the pinion, and starts to trail. It is impossible for there not to be any play in the hour hand during setting: remember this is effectively a clutched part that has to both jump during setting and crawl during normal running. However, it must of course settle down to an equilibrium position once everything has ‘caught up’ after setting – and this position should be in sync with the minute hand.

Our fix for this involves a recalibrated spring/tooth profile on the jumper cam, for more holding tension and a crisper ‘snap’ into place (steeper profile, thus more engagement force) and a tension washer between the hour gear and dial. The setting mechanism we cannot change, but the baseline force holding the hour wheel in place is now higher than the residual setting drag. Even so, we now advise backwinding the crown one turn to ensure the keyless works are fully disengaged after setting the independent hours.

We realize that the whole process felt agonisingly slow from the outside. Given several variants of tooth and cam profiles had to be calculated, produced, tested (with borderline abusive treatment to replicate the most extreme real world scenarios), refined, put into raw production, finished, etc. and a month was lost to the Swiss watchmaking industry shutting down for its customary summer break and sub-suppliers up and down the line being closed - we did the best we could.

The new components have been fitted to 17.09 Massena LAB watches that were returned with alignment issues, and will continue to be retrofitted to other watches that may not display any issues but come in for service at a later date. They are also fitted to all 17.09 Blue and Burgundy watches as standard. As an expression of confidence in the modifications, we have extended the warranty on all 17.09s to a total of three years from the date of delivery.

- MT

Published: January 2022